Phenol formaldehyde resins (PF) are synthetic polymers obtained by the reaction of phenol or substituted phenol with formaldehyde. Used as the basis for Bakelite, PFs were the first commercial synthetic resins (plastics). They have been widely used for the production of molded products including billiard balls, laboratory countertops, and as coatings and adhesives. They were at one time the primary material used for the production of circuit boards but have been largely replaced with epoxy resins and fiberglass cloth, as with fire-resistant FR-4 circuit board materials.

Trade names

- Bakelite is made from phenolic resin and wood flour.

- Novotext is cotton fibre-reinforced phenolic, using randomly oriented fibres.

- Oasis is "an open-celled phenolic foam that readily absorbs water and is used as a base for flower arrangements."

- Maritex Aquarius is a very high performance bearing material made using novolac resin, fibre reinforcement and added lubricants for momentary dry run situations. It is also used dry at slow speeds and high pressures, showing very low wear rates of shaft or bearing.

Color chart for Bakelite "Jewel" quality colors (cast resin or "Clear Material"), 1924

Wood flour is finely pulverized wood that has a consistency fairly equal to sand or sawdust, but can vary considerably, with particles ranging in size from a fine powder to roughly the size of a grain of rice.

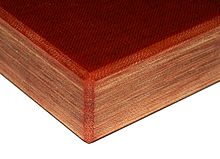

Tufnol (Novotext) plate

Production is achieved through the use of chopped strand mat (CSM) technique.

Production is achieved through the use of chopped strand mat (CSM) technique.

No comments:

Post a Comment